- Tel: +86 13915290614

- E-mail: zhulin@zozen.com

- Production Base: No.76 Xinda Rd.,Zhoutie Town, Yixing City, Jiangsu Province, China.

- Customer Service Center: No. 777 Jianzhu West Road, Binhu District, Wuxi, China.

- +86 13915290614

- zhulin@zozen.com

- Home

-

Products

- Oil/Gas Fired Boiler 1. WNS series gas-fired (oil-fired) steam boiler 2. SZS series gas-fired (oil-fired) steam boiler 3. WNS series gas-fired (oil-fired) hot water boiler 4. SZS series gas-fired (oil-fired) hot water boiler 5. DHS series medium temperature medium pressure gas-fired (oil-fired) boiler

- Coal Fired Boiler 1. SZL series coal-fired steam boiler 2. DZL series coal-fired steam boiler 3. DHL series coal-fired steam boiler 4. SZL series coal-fired hot water boiler 5. DZL series coal-fired hot water boiler 6. DHL series coal-fired hot water boiler 7. SHL series double drum bulk chain grate boiler

- Biomass Fired Boiler 1. DZL series biomass-fired steam boiler 2. SZL series biomass-fired steam boiler 3. DZL series biomass-fired hot water boiler 4. SZL series biomass-fired hot water boiler 5. DHL series biomass corner tube chain grate hot water boiler 6. SHL series biomass bulk chain grate steam boiler

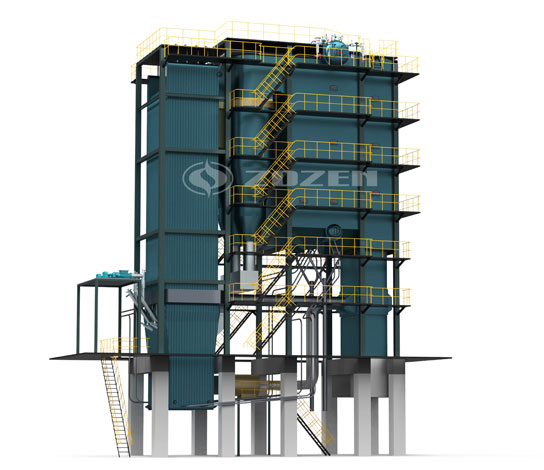

- CFB(circulating fluidized bed) Boiler 1. SHX series CFB steam boiler 2. SHX series CFB hot water boiler 3. DHX series CFB steam boiler 4. QXX series CFB hot water boiler

- Thermal Fluid Heaters 1.YLW series coal-fired thermal fluid heater 2. YQL series gas-fired thermal fluid heater 3. YQW series gas-fired horizontal thermal fluid heater 4. RYQ series molten salt heater

- Application

- About Us

- Case

- Services

- News

- Contact Us