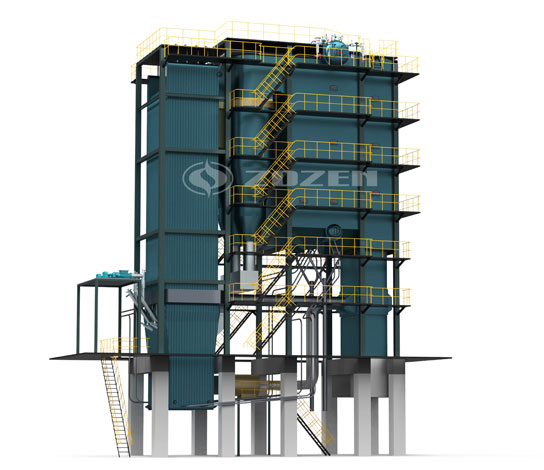

Description

SZL series vertical dual drums chain grate water pipe steam and hot water boiler, adopts quick fitting and assembly structure. The 4-6t/h boiler is of quick fitting pipe structure, exit shop after completely assembled, the boiler of 6-35t/h is composed of 2 main components. The upper assembled components is the body heat accepting part, and the lower assembled component is of combustion equipment.

The former part of the boiler body is arranged an water cooling wall, the upper part of it is connected to boiler cylinder, and its lower part is connected to collective chest, so as to form a combustion room and absorb the radiated heat from the furnace. Its rear part is arranged with dense convection pipes between upper and lower boiler cylinders. The high temperature smog after combustion shall stand for twice returning flushing transversely to the heat accepting surfaces, and shall be introduced to coal saver singly arranged, and flow into duster and exhausted from chimney in the end.

Technical advantages

1. The key processing technologies such as steel plate blanking, circling, drilling of drum and pipe plate are all adopt advanced CNC processing to reduce the assembly stress and prolong the service life of the boiler.

2. Automatic production line.

3. The welding of important parts like the vertical and circular seams of the boiler, the pipes, the inside of boiler and the flange are all adopted automated welding processes such as submerged arc welding or gas shielded welding to ensure the welding quality. All the vertical and circular seams will be done 100% radiographic inspection.

4. The user can reasonably distribute the air according to different combustion conditions to ensure that the fuel is fully burned.

5. Graded air supply and special furnace arch structure make the NOx emissions down to 100mg/m³.

6. The key part such as material cutting, rolling, drilling are proceeded by advanced CNC machining process to reduce the assemble stress and extend boiler working lifetime.

7. flutter prevention fastener is used for high temperature part convection tube, which avoid bundle tube cracking problem.