The thermal oil heater is a boiler that uses heat-conducting oil as heat medium to transfer heat. With the high-temperature characteristics of heat-conducting oil, thermal oil heaters can supply heat at low pressure and high temperature, and are widely used in the daily operation of other industries such as petroleum, chemical industry, pharmaceutical industry, textile printing and dyeing, light industry, building materials, food, road asphalt heating, etc. So, do you know the structure of gas-fired thermal oil heater?

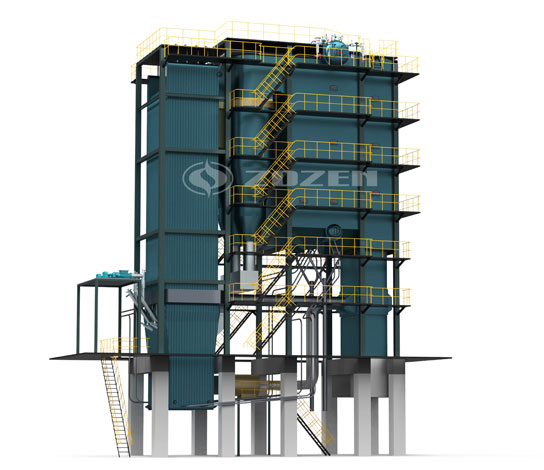

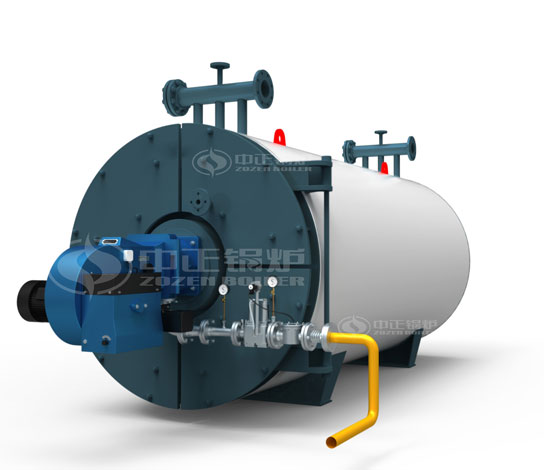

ZOZEN gas-fired thermal oil heater adopts a three-return disc tube structure, and the end of the coil adopts a necking coil, which effectively protects the furnace wall at the end of the boiler, and is equipped with an advanced combustion device, so that the boiler runs fully automatically. After the fuel is ignited by the burner, the formed torch fills the circular tube and transmits radiant heat through the wall of the coil, which is the first pass. The high-temperature flue gas generated by combustion converges at the rear furnace door and turns into the second pass, namely the convection tube bundle area. After convection heat exchange, the flue gas temperature gradually decreases and then reaches the front furnace door, where it turns into the third pass tube bundle area, and then enters the chimney through the economizer and is discharged to the atmosphere.

The basic configuration of gas-fired thermal oil heater system includes the following main parts:

1. Combustion system: furnace, burner, ignition device, etc.

2. Oil circulation system: circulating oil pump, oil injection pump, storage tank, expansion tank, etc.

3. Control system: matched with boiler control box.

4. Smoke system: refers to the system composed of flue gas and air generated by combustion, mainly including induced draft fan, chimney and other equipment.

The specific configuration of gas-fired thermal oil heater system will be different according to the specific needs of users and actual working conditions, to realize green and efficient heat energy conversion.