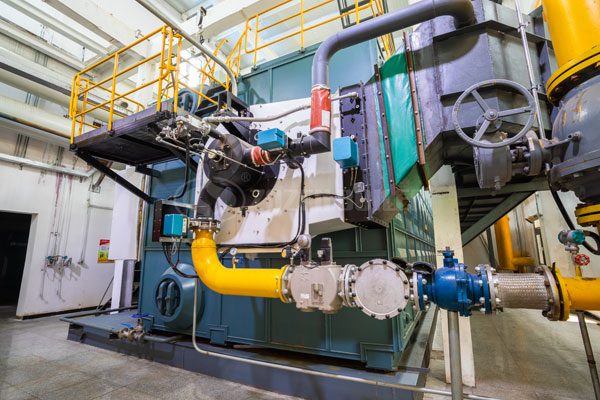

The quality assurance system of ZOZEN boiler is composed of quality management, quality control and product quality inspection stages and links. In the control procedure, the quality assurance engineer under the leadership of the general manager - the professional responsible engineer - the professional and technical personnel of the functional departments should be three-level responsibility system, and they should coordinate and cooperate with each other to operate reasonably. The hot water boiler designed by ZOZEN boiler has unique and reasonable system, which is a mature system rarely seen at present.

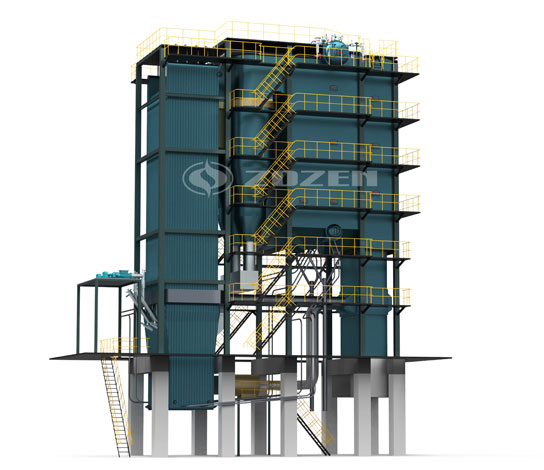

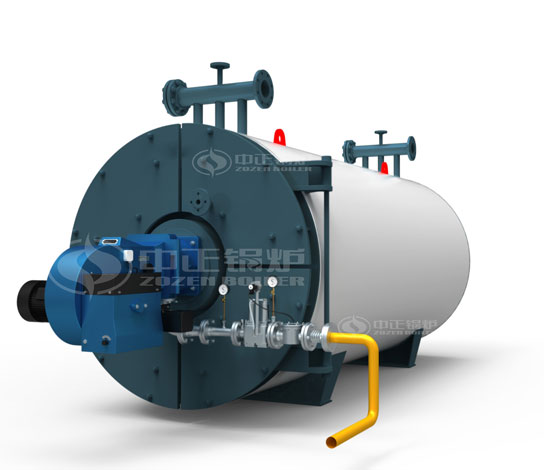

The planning of hot water boilers and their systems should meet the requirements of relevant national energy-saving laws, regulations, safety technical specifications and their corresponding specifications. Boiler incineration equipment and furnace structure are planned reasonably, which is in line with the planned fuel types to ensure safe, stable and efficient incineration. Reasonable placement of heating surface. Choose reasonable and economical flue gas velocity and reduce the resistance of flue gas side. It ensures that the air leakage coefficient of hot water boiler is within the planning requirements.

In the planning of the boiler room system, the efficiency of power utilization should be improved, water, electricity and other consumption should be reduced, and the recovery of heat energy and ladder application should be promoted on the premise of ensuring the safety function. The length of pipes and flue ducts and the number of elbows should be reduced as far as possible in order to reduce the moving resistance when installing equipment in boiler rooms.

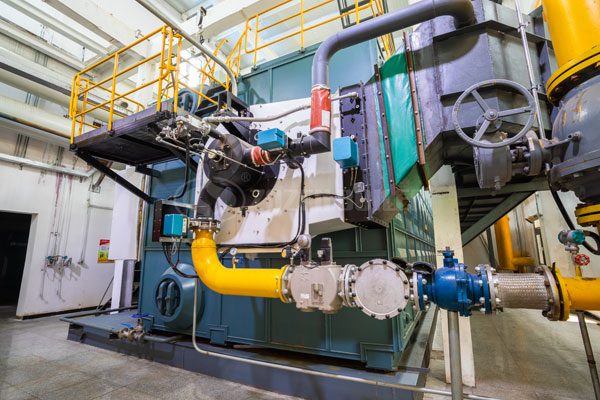

When the user's heat load fluctuates greatly and frequently, the method of balancing load should be adopted to achieve useful conditioning. The system of multiple boilers should be equipped with centralized control equipment to ensure the balance of boiler operation and economic operation. The selection of boiler medium parameters should meet the requirements of operation, and the difference between the additional outlet pressure and temperature of the boiler and the pressure and temperature of operation should not be too large.

The heat of the sewage from hot water boilers should be used reasonably, and a series of blowdown expanders should be set up according to the total amount of the blowdown from the boilers. Boilers and their systems should eliminate running, leaking, dripping and leaking, make full use of the heat of sewage, and adopt measures to increase the utilization rate of recoverable condensate as much as possible.